Servicing Hydraulics in Moranbah

Contact Rowdraulics NQ in Moranbah

Hydraulics & Engineering Services

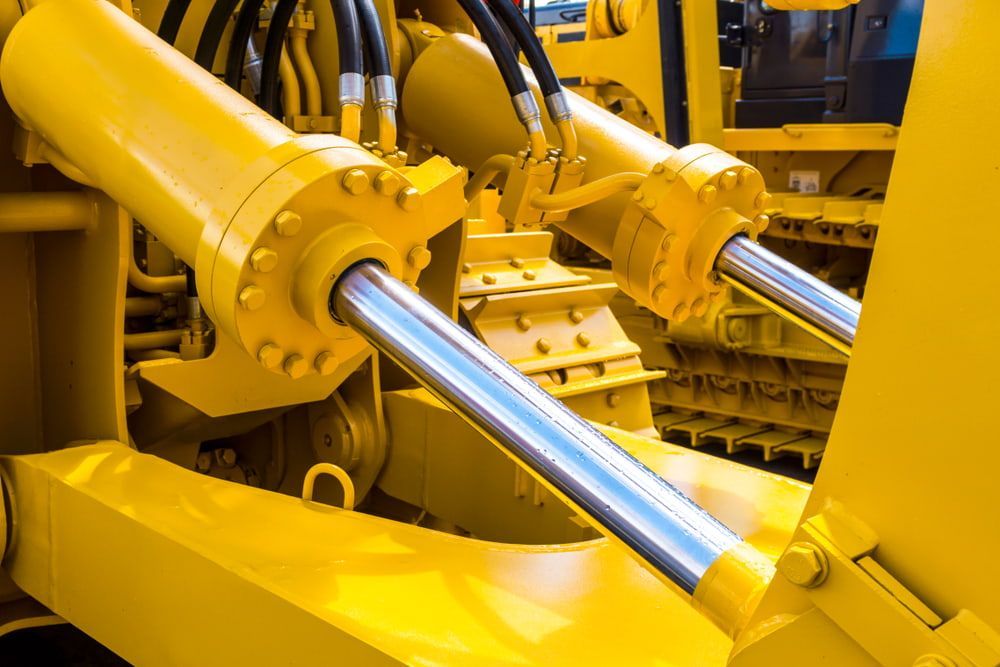

Established in 1994, Rowdraulics NQ stands as a pillar of the Moranbah industrial landscape, offering unrivalled expertise in hydraulic and general engineering services. Our reputation as one of the town’s most seasoned hydraulics providers reflects our ability to easily tackle even the most complex tasks, including hydraulic hose fittings, hydraulic pump and motor repairs and tipper hoist maintenance. We also service hydraulic cylinders.

At Rowdraulics NQ, we commit to affordability without sacrificing quality, ensuring superior service remains accessible to all. For expert guidance and service, contact our hydraulic specialists directly on

0413 049 674.

We offer servicing throughout

Dysart,

Middlemount,

Blackwater,

Emerald,

Clearmont, and the surrounding areas, guaranteeing comprehensive support for all locales in between.

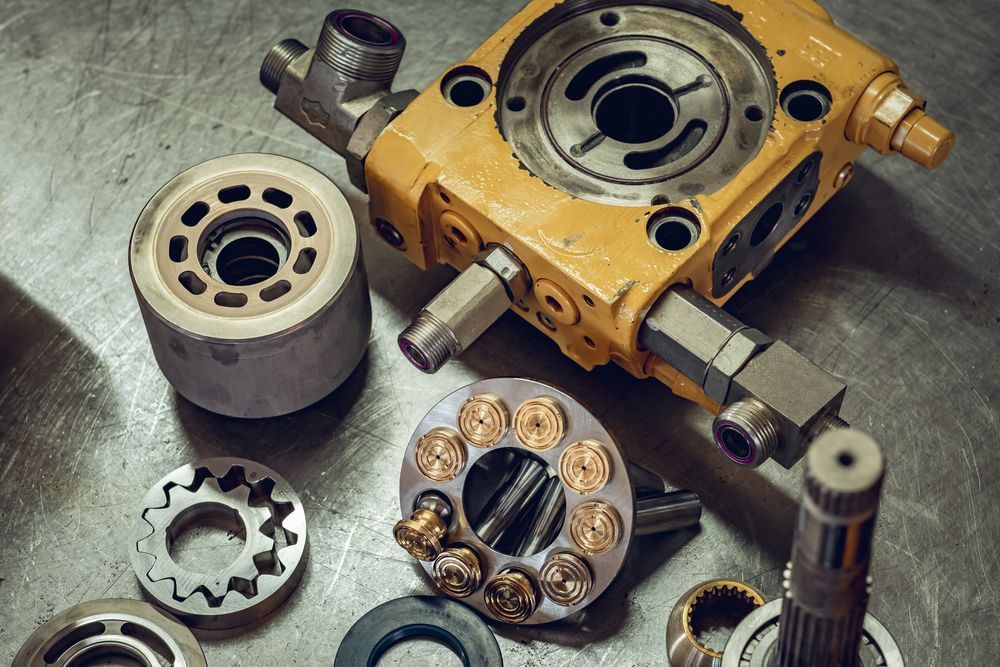

Our expertise lies in hydraulic pump and motor repairs in Moranbah, using top-notch parts and following manufacturer specs to bring systems back to peak performance.

Specialising in hydraulic cylinder servicing in Moranbah, our technicians repair seals, rods, barrels and pistons—using top-quality Gates products for optimal efficiency.

Experts in repairing all hydraulic components in Moranbah, especially valves, we quickly address leaks or slow operation, ensuring your equipment is diagnosed and fixed promptly.

Seeking a truck tipper hoist or repairs? We've got you covered with same-day service in Moranbah for seal replacements. No need to look elsewhere.

Offering general engineering in Moranbah, design, fabrication and assembly of bespoke components, we guarantee high-quality machining and fabrication services tailored to your needs.

Commercial and industrial clients rely on us for hydraulic hose repair and replacement, offering 24/7 emergency mobile services directly to your location in Moranbah.

Hydraulic System Maintenance Benefits

Regular maintenance of hydraulic systems offers several pivotal benefits that cannot be overlooked. Firstly, it significantly reduces the likelihood of system failures, which can be costly and hazardous. Ensuring all components are functioning optimally minimises the risk of unexpected downtime, thus safeguarding continuous operational efficiency. Furthermore, preventative maintenance extends the lifespan of the hydraulic equipment.

Companies can avoid premature equipment replacement by identifying and addressing issues, such as leaks, contamination and part wear, before they escalate, leading to substantial financial savings. Additionally, consistent maintenance routines improve the overall safety of the work environment. By preventing malfunctions and leaks, the risk of accidents and injuries to personnel is reduced, promoting a safer and more secure workplace. Ultimately, investing in the regular upkeep of hydraulic systems is not just financially wise but also enhances operational reliability and ensures a safer work environment for all involved.

Hydraulic System Issues

Hydraulic system issues can manifest in various forms, significantly affecting efficiency and safety in industrial applications. Common problems include leaks, which not only waste fluid but can also lead to contamination and environmental hazards. Contamination, another frequent issue, can result from the ingress of water, air or particulate matter, potentially causing system inefficiencies, corrosion or failure. Overheating, often a consequence of overuse or inadequate cooling, can degrade hydraulic fluids, affecting their performance and longevity. Additionally, improper maintenance or irregular fluid changes can lead to a build-up of sludge and varnish, obstructing valves and filters and further impeding system performance.

Addressing these challenges requires diligent maintenance, regular system checks and adhering to operational guidelines, ensuring the longevity and reliability of hydraulic systems. It's crucial to have a sound understanding of system specifications and to utilise quality fluids and components, minimising the risk of hydraulic issues and extending the operational lifespan of the machinery.

Contact Rowdraulics NQ in Moranbah

Phone

Location

Business Hours

- Monday

- -

- Tuesday

- -

- Wednesday

- -

- Thursday

- -

- Friday

- -

- Saturday

- Closed

- Sunday

- Closed

On call 24/7